Brake Valves

| Single Modulating Valve |

Tandem Modulating Valve |  |

| Reverse Modulating Valve |

Custom Engineered |  |

Related Product Information

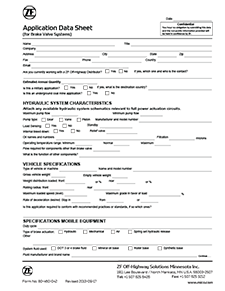

This sheet is used for Brake Valve System applications.

ZF uses application data sheets to collect machine and/or vehicle information specific to an application. They are also helpful for understanding the environment and manner in which the machine/vehicle will be operated. Our Engineering Department uses application data sheet information to select suitable brake components that are designed to meet your application needs.

ZF holds this information in strict confidence. Your machine/vehicle information is strictly for application assistance and will not be sold or shared with anyone outside of ZF.

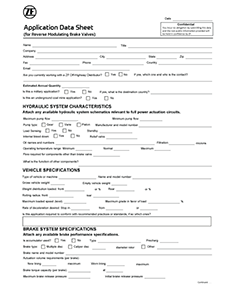

This sheet is used for Reverse Modulating Brake Valve applications. These valves are intended for mobile equipment and are normally used in conjunction with spring apply hydraulic release brakes.

ZF uses application data sheets to collect machine and/or vehicle information specific to an application. They are also helpful for understanding the environment and manner in which the machine/vehicle will be operated. Our Engineering Department uses application data sheet information to select suitable brake components that are designed to meet your application needs.

ZF holds this information in strict confidence. Your machine/vehicle information is strictly for application assistance and will not be sold or shared with anyone outside of ZF.

This 64-page catalog is loaded with features, model numbers and specifications.

This is our introductory catalog for ZF Off-Highway Solutions Minnesota Inc. products. It provides product photos and brief descriptions of the product portfolio offerings in brakes, brake actuation, valves, and controls.